TECNO 3F.P. S.r.l. was born in 2008 starting from our passion and experience gained over the years in the mechanical, electronics and carpentry sectors.

About us

Mission

Our goal is to be your partner and not just a supplier. We want to guarantee excellent solutions in a short time, combining the punctuality that distinguishes us with continuous innovation, and to work alongside our customers to face the challenges that the market offers.

Technology and innovation

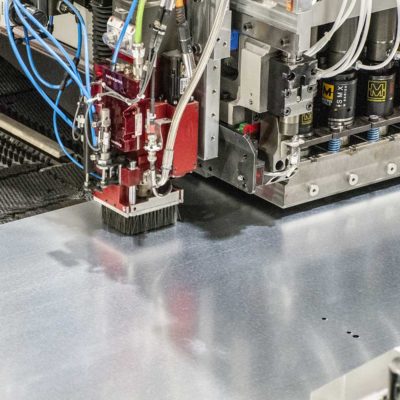

We are constantly updated on new technologies and methods to provide not only a high quality standard through a cutting-edge production system, but also to anticipate the future in the field of laser cutting, bending, calendering and welding of different types of materials.

Certifications

In 2019 we obtained many certifications:

- UNI EN ISO 9001: 2015 for QUALITY to provide our customers with a top-quality standard;

- UNI EN ISO 14001: 2015 for the ENVIRONMENT which has brought us in closer contact with the green and energy saving world;

- UNI EN ISO 45001: 2018 for HEALTH AND SAFETY AT WORK in order to have an informed team of workers, with greater control over risks and therefore a reduction in dangers;

- UNI EN ISO EN 1090-1:2009+A1:2011 that have given us the possibility of producing STEEL STRUCTURAL COMPONENTS respecting the QUALITY REQUIREMENTS FOR FUSION WELDING of metallic materials.

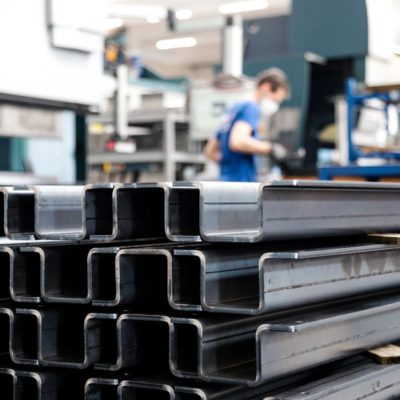

From large orders to single pieces

With the aim of meeting the needs of a market increasingly looking for tailor-made solutions, we have expanded our expertise in this sector, which has always been dedicated to large orders, to anticipate the requirements of the market and respond professionally to the demands of increasingly specialised customers.

We handle both large and small orders with the same precision and high quality results.

Areas of expertise

Our processes range across various sectors.

Agriculture, food industry, production of machine tools, industries for the construction of special machines, plants for the bottling sector, goldsmiths, electronics and electro-mechanics, furniture: our flexibility is the key to meeting the needs of various fields of application with precision.

Processing and design

In addition to specific processes, we also offer advice and support to our customers in the design phase backed by our many years of experience in this field.

Our team of specialised technicians and engineers is available to design and develop mechanical and carpentry parts, supported by our machines that offer flexible production processes.

We adopt the most advanced technologies to process any type and format of material and this allows us to deal with all aspects of the product life cycle: from design to development, from planning to job orders, from the finishing treatment to the final assembly.

Confidentiality protects your ideas

We work for companies that operate with high engineering or design standards, so we always maintain the utmost confidentiality and, when requested, the exclusivity of the proposed solutions.

Types of material processed

Our machines and equipment can process materials with very different characteristics: steel, stainless steel, galvanized sheet metal, aluminium, copper and brass, also pre-painted.

Our plants, our team

We operate out of two structures for a total of about 6,000 sq.mt. of buildings:

- REGISTERED OFFICE, via Magellano, 13 in Cerea

- CUTTING CENTRE, via Ponzina, 1 in Legnago

- WELDING CENTRE, via Magellano, 5 in Cerea

We have almost 70 employees including technicians, specialists, designers and workers that every day put all their expertise and passion in developing your projects.

Respect for the environment

We have always had a strong commitment to the environment.

We have a solar panel system for energy saving and we aim to become autonomous in the next few years by producing the energy necessary for our activities.

In 2019 we obtained the UNI EN ISO 14001: 2015 environmental certification (LINK). In line with our Green objectives, we have also installed water dispensers in both our plants and given each employee a steel bottle to be completely plastic-free.

In both our plants we have almost completely eliminated the production of non-recyclable waste by sorting waste very carefully and inviting our employees to do the same. All industrial waste is correctly managed in all stages: collection, sorting, treatment, recovery and disposal are carried out according to the regulations in force using only authorised companies.

Via Magellano, 13

37053 Cherubine di Cerea (VR) Italy